Mixing and grinding from a single source

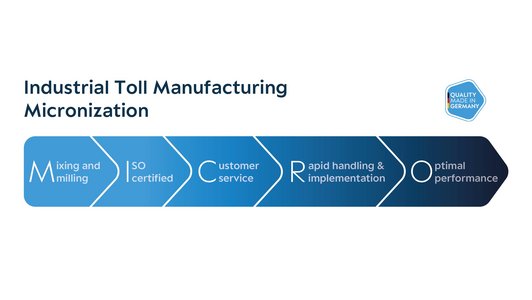

Toll micronization

Our Know-How

We combine 100 years of tradition with innovation.

- Over the years we have built-up a wealth of expertise in micronizing products. We can now draw upon our experience of more than 20 years in this field.

- We can offer you an excellent customised process development service as well as a quality service from our own labs within our research and development department.

- Our day-to-day business is to manufacture, micronize and mix a wide range of substances.

- We can mix, micronize and homogeneously fill substances with a wide range of particle sizes.

We offer the best service.

Efficiency

- We offer you a tailored toll manufacturing service of the highest quality.

- Excellent milling skills using state of the art air jet mills are combined with highly effective blending machines to create our own special mixing and fine milling capabilities.

- Our technology results in reduced emissions and minimal waste formation.

- Our quality systems for process control and finished product quality ensures a standard which should meet even the highest requirements.

- Various qualified analytical methods are available to ensure product quality assurance.

Several individual milling lines provide a high level of flexibility.

Flexibility

- A separate mill for pilot projects and small quantity campaigns enables flexible milling quantities ranging from kilograms to multi-tonne volumes.

- We offer the possibility of various packaging variations to suit your needs.

- Our speciality – we can mix and micronize your products to meet your every requirement.

- Flexible logistic – we can arrange the optimal logistic handling for your products.

With our technical prerequisites we can supply optimal results.

The highest level

- accurate fine milling with minimal particle size distributions

- micro particle sizes down to 1,5 μm (d50-value)

- minimum ignition energy (MIE) ≥ 1 mJ

- dust explosion classes 1 & 2

- maximum explosion pressure of 10 bar

- no thermo contamination during micronization

- inert milling conditions (for small quantities)

Contact

Bastian Berger