Dicyandiamide

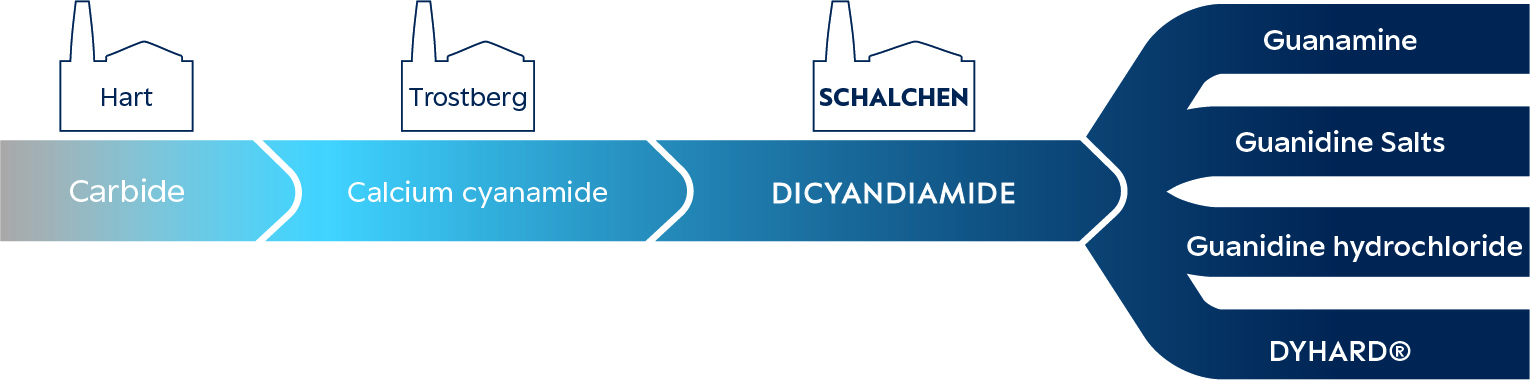

Alzchem AG (formerly known as SKW Trostberg), has been producing Dicyandiamide (DCD) at its technically advanced and environmentally friendly plant in Schalchen since 1950. With an annual capacity of 25,000 tons, it is one of the largest in the world and the only DCD source outside of China.

DCD is used in a wide range of applications. For example, as a synthesis building block in active pharmaceutical ingredients (API’s) such as Metformin, as a hardener in epoxy industry applications and as a nitrification inhibitor for agricultural fertilisers. Alzchem also uses DCD internally as a raw material for forward-integrated intermediates for the production of guanidine salts, guanamines and DCD-based condensation products, which are used in areas such as airbags, wastewater treatment, flame retardants, textiles and leather, and pulp and paper.

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/3/6/csm_AdobeStock_77178317_petrischale_pulver_weiss_Syda_Productions_477c277a26.jpg)

Backward integrated in the production of Dicyandiamide

TROPHARM

High purity Dicyandiamide (at least 99.7%) with low impurities (e.g. Melamine) for pharmaceutical application

DYHARD® 03

High purity Dicyandiamide with low turbidity levels for Printed Circuit Board industry

DCD

Standard Dicyandiamide grade for general industrial applications

TROMID

Basic grade Dicyandiamide with special specs for basic industrial use, like paper industry

Applications

Starting Material for Metformin

- TROPHARM is a high-purity dicyandiamide grade

- Used in large quantities in the pharmaceutical industry as a starting material to produce Metformin

- Metformin is used for the treatment of type 2 diabetes

Long-lasting Nitrogen Fertilizer

- DCD is used in agriculture to stabilize urea

- It increases the useful period of the fertilizer and prevents the environmentally harmful leaching of nitrates on fertilized fields

DYHARD® 03

- Is used as a hardener for epoxy resin applications

- Printed Circuit Boards (PCB) are typically made from glass fiber which are impregnated with epoxy resin, hardeners and accelerators

- Multiple layers are laminated under high pressure and cured with Dicyandiamide

DCD-Formaldehyde-Polycondensates

- Used to improve wet strength of colourations and prints (Dyefixing) and to enhance crease resistance

- Act as a formaldehyde acceptor in high-grade textile finishing (refining)

- Also used for flame-resistant finishing in textiles, often in combination with phosphates

Flame retardant additive

- Impregnation of paper or wood to achieve flame-retardant properties:

e.g. filter media for clean air in engines - DCD as a substitute for melamine in intumescent coatings: additive in fire protection

Flocculating Agents

- Dicyandiamide and formaldehyde based cationic resins

- Used in industrial wastewater treatment

- Primarily applied in flocculation of wastewater plants, paper mills and the dyestuff industry

Your Advantages with Alzchem

Reliability and high quality

Alzchem Dicyandiamide is 100% backward integrated and fully "Made in Germany". It is the only remaining dicyandiamide plant outside of China.

Our product portfolio

Alzchem offers a specific product for several applications as well as customized packaging (big bag, paper bag).

Environment, health and safety

Alzchem has one of the most efficient, technically advanced and environmentally friendly DCD processes.

Our know-how and experience

Alzchem has been producing Dicyandiamide since 1950. Our knowledge is based on more than 70 years of experience and expertise in the manufacturing of Dicyandiamide.

Our customer orientation

Our focus is on long-term customer relationships. Partners receive a high standard of service including technical and customer-specific support.

ISO 9001 / ISO 14001 / ISO 50001

ISO-certified production site.

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/d/3/csm_15_100S_f7610f178d.jpg)